Tin tức

Quality Control in PCB Test: Ensuring Reliable Performance

Quality Control in PCB Test: Ensuring Reliable Performance

In today’s highly competitive electronics industry, the quality of printed circuit boards (PCBs) plays a crucial role in determining the success or failure of electronic devices. To ensure reliable performance, rigorous testing and quality control measures are implemented throughout the production process. In this article, we will delve into the importance of pcb board testing and explore how it contributes to overall quality control in logistics.

The Significance of PCB Board Testing

PCB board testing is an essential step in ensuring that electronic devices function as intended. It involves subjecting the boards to various tests to identify any defects or faults before they are integrated into final products. By conducting thorough inspections and assessments during this stage, manufacturers can detect potential issues early on and prevent costly failures later.

During PCB board testing, multiple aspects are evaluated including electrical connectivity, signal integrity, component placement accuracy, solder joint reliability, and thermal performance. These tests help identify manufacturing flaws such as short circuits, open circuits, incorrect component values or placements that may lead to malfunctions or even safety hazards.

The Importance of Rigorous PCB Testing

Rigorous pcb test ing is vital for maintaining high-quality standards throughout the logistics process. It ensures that only defect-free boards proceed further down the supply chain while faulty ones are rejected for rework or disposal. This helps minimize product recalls and customer dissatisfaction due to malfunctioning devices.

Moreover, comprehensive testing also aids in identifying any design flaws that might impact product functionality or durability over time. By addressing these issues at an early stage through effective quality control measures like stringent test protocols and inspection criteria set by international standards organizations such as IPC-A-600G (Acceptability of Printed Boards), manufacturers can enhance their reputation for delivering reliable products.

JinHua: A Leading Player in PCB Testing

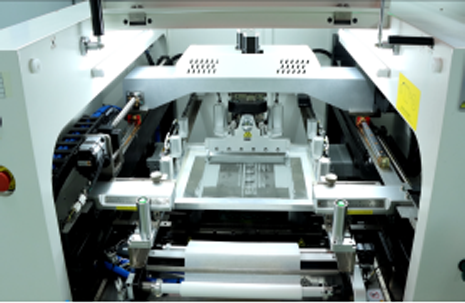

When it comes to PCB testing, JinHua has emerged as a prominent player in the industry. With state-of-the-art facilities and advanced testing equipment, they offer comprehensive solutions for ensuring the quality and reliability of printed circuit boards.

JinHua’s expertise lies not only in conducting standard tests but also in customizing test procedures based on specific customer requirements. Their team of highly skilled technicians and engineers meticulously analyze each board, employing cutting-edge techniques such as automated optical inspection (AOI), X-ray inspection, flying probe testing, and environmental stress screening (ESS) to guarantee optimal performance.

Conclusion

In conclusion, PCB board testing is an integral part of quality control in logistics within the electronics industry. By subjecting boards to rigorous tests at various stages of production, manufacturers can identify defects early on and ensure that only high-quality products reach consumers. Companies like JinHua play a crucial role by providing specialized services that contribute to overall quality assurance. Emphasizing thorough PCB testing helps maintain customer satisfaction while upholding the reputation for delivering reliable electronic devices.